CHEERS research reports now available for downloading

The CHEERS project is approaching its next major milestone: The start of procuring and building its 3MWth Chemical Looping Combustion (CLC) demonstration facility in China.

The path to this milestone includes a comprehensive set of R&D activities from small-scale reactivity measurements in the laboratory to pilot plant testing, advanced numerical modelling, and flow testing and measurement on a 1:2 scale copy of the planned 3MWth demo facility. Our researchers have documented this work in detail for the benefit of not just CLC developers, but the greater community of technologists working to bring new, improved low-emissions solutions to market.

This is already being facilitated in a number of ways. To compliment these, the CHEERS project has now made available its completed research reports for downloading from the project website. See the ‘Results’ tab on the front page of the website. Some of the research reports are confidential. In this case, only the front page and the publicly available abstract are downloadable.

There is also a pdf file (also downloadable) containing a screen shot of the front page of externally published technical articles from the CHEERS project (i.e. peer-reviewed journal papers or conference proceedings). These can be found on the ‘Cross-Work Package Publications’ tab under ‘Results’.

Recording from our WP2 webinar on July 1, 2021

In case you missed it, or want to revisit the webinar held by WP2 on July 1, 2021, simply follow the link to the recording on our Youtube channel.

Webinar Invitation: Thursday July 1, 09:30-10:45 CET

On behalf of the CHEERS CLC project, Bellona is pleased to invite you to a webinar highlighting the main results from the Work Package 2 ‘Development and Design Studies’. This activity has been led by IFP Energies nouvelles (IFPEN).

This webinar will summarize the research results on the following themes:

· The dual Sino-European CLC design

· 1.5 MW CLC cold flow model design and operation

· Pre-FEED of the 3 MW CHEERS demonstration unit

The ambition of the CHEERS project is to improve the efficacy of CO2 capture in industry, and help ensuring sustainable, secure, and affordable energy. This will be achieved by testing and verifying a 2nd generation chemical-looping technology, first at laboratory scale (150kWth), then developing into a 3MWth system prototype for demonstration in an operational environment.

Please register here.

The CHEERS CLC project has received funding from the European Union’s Horizon 2020 research and innovation program under grant agreement No 764697. The project is also co-funded by the Chinese Ministry of Science and Technology (MOST).

For more information about the CHEERS CLC project, please visit our website

Please feel free to forward this invitation to people in your network.

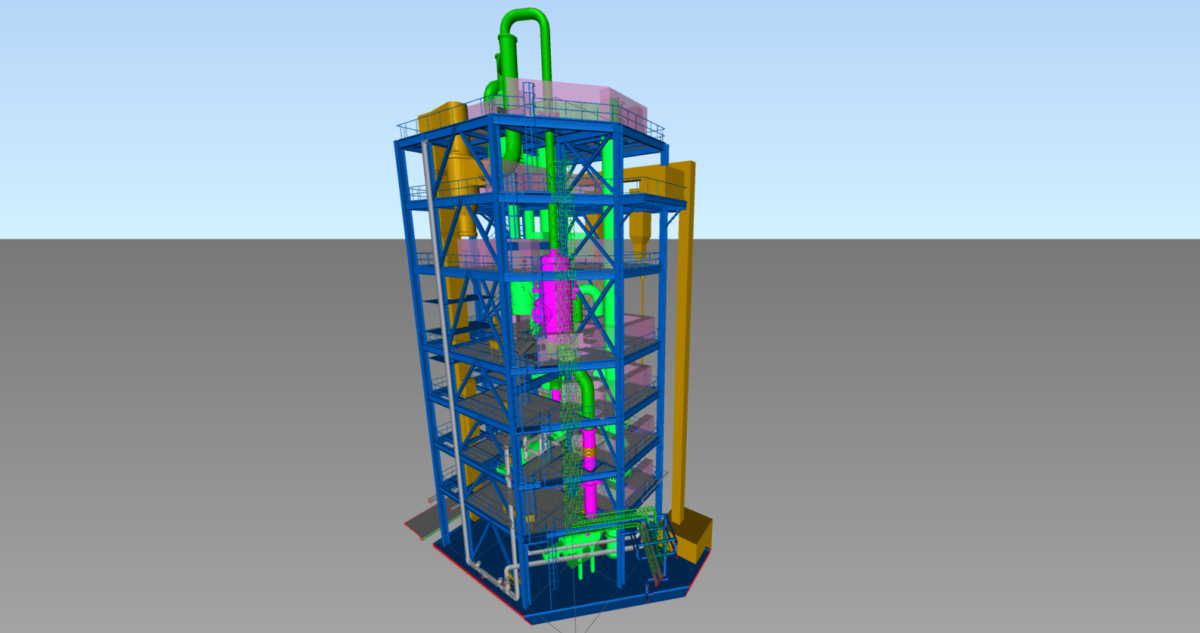

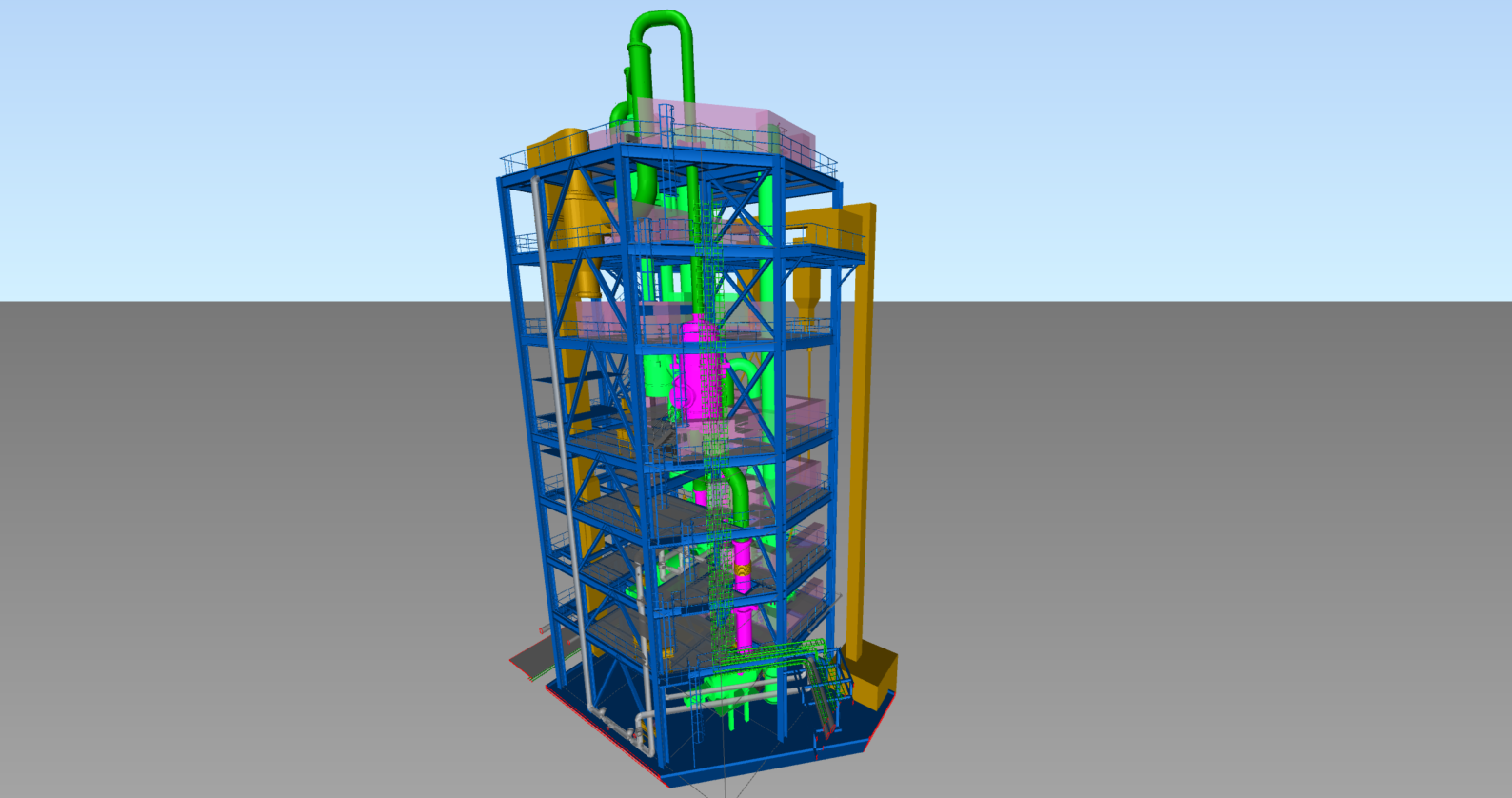

A 3-D engineering rendering of the planned demonstration plant

The CHEERS team adds a new peer-reviewed publication to its growing list

The CHEERS project has achieved several research objectives in its quest to design, build and operate what will be the world’s largest demonstration CLC facility.

One of its areas of research has focused on understanding how the particles of fuel and oxygen carriers evolve as they chemically react, change size and density as they pass through the various chambers of the complete CLC system.

The CHEERS team is proud to announce publication of research results in the peer-reviewed journal Combustion and Flame, where the drag force acting on a fully reacting fuel particle is studied and explained in great detail.

This is essential knowledge for an optimal system design, which involves finding the right balance between flow rates, reactor height and diameter, as well as a long list of operating parameters and modes.

One step closer to industrializing a new carbon-free energy production technology

The front-end engineering design (FEED) phase of the Chinese-European Emission-Reducing Solutions (CHEERS) project has now started – a major milestone in this project. When finished, it will be the world’s largest chemical looping combustion (CLC) demonstration plant.

The project is the last step before an industry-wide deployment of CLC technology. CLC generates steam for industrial applications or electrical power, without CO2 emissions thanks to its built-in ability to separate CO2. This means CLC can produce energy with zero carbon content. In addition, It can produce energy with negative carbon content when using feedstocks such as biomass. In this case, CLC enables the indirect capture of CO2 from the atmosphere, and the reduction of greenhouse gas content to the atmosphere.

The demonstration plant – to be built in China – will test the second-generation CLC technology at a capacity of 3MW and will be the largest of its kind using this new fuel-conversion technology in an operational environment.

A 3-D engineering rendering of the planned demonstration plant

The ground-breaking concept has the potential to increase the efficiency of CO2 capture significantly, compared to existing carbon capture technologies and can remove up to 96 per cent of combustion-related CO2. The project offers a viable path to retrofit industrial combustion processes and is a major step towards the large-scale decarbonization of the refining, chemical and power industries.

Managed by TOTAL, the FEED was awarded to Worley, who will carry out the services from its Belgium and China offices. Once completed, the FEED results will be handed over to Dongfang Boiler Group Co Ltd, who will manage the detailed engineering, procurement and construction (EPC) of the plant.

The CHEERS project is financed partially by the EU’s Horizon 2020 Research and Innovation Programme and the Chinese Ministry of Science and Technology, with financial and industrial support from TOTAL, Dongfang Boiler Group Co Ltd, and other project partners.

How to design the flow inside a CLC installation

The CHEERS project continues its design and verification work based on the cold flow rig described in a previous post. In this newly produced video of the cold flow rig, more detail and description are provided on the subsystems and components involved.

A very important intermediate step is to build a visualization rig that looks very much like a working CLC plant, but does not use fuel. Instead, it circulates the particles used to transfer oxygen to the fuel in a nitrogen-free environment.

The cold flow rig (sometimes called a cold flow mock-up) was designed, built and installed by our CHEERS partners in Europe and China. This video highlights the special design details implemented on the cold flow rig for European design specifications.

If you are interested in the technical details behind this, then you can read our CHEERS researchers recently submitted article to the peer-reviewed journal Energy&Fuels. This article has been accepted for publication after final formatting for the printed version of the journal.

But if you would simply like to watch the new video with more complete description of the cold flow rig in action, here it comes.

Special thanks goes to our CHEERS project partner IFP Energies nouvelles for producing and editing this new video.

Chemical Looping Combustion: how it works in a new video

The global warming challenge is one of the greatest innovation opportunities going forward. One strategy is to re-invent combustion from scratch to promote more efficient CO2 capture. A very promising such solution is Chemical Looping Combustion (CLC).

The Cheers project is developing Chemical Looping Combustion (CLC) to the next level. CLC is an energy production technology leveraging inherent, built-in, CO2 capture. This reduces the need for investment in dedicated CO2 separation from low-concentration flue gases. It also reduces operational costs because it uses less energy in its inherent CO2 separation process.

Designing a full-scale CLC plant is still a work in progress. The current fleet of CLC test rigs are made and used for basic research and development. These are now ready to be scaled up to dimensions suitable for commercial application.

The CHEERS project has produced the design basis of a 3 MWth demonstration CLC facility with systems that will allow researchers to understand how to make it even better in the next version. This design basis is now being converted to a Front End Engineering and Design (FEED) by a world-renowned engineering contractor. This will be announced in a post coming soon.

The animation below shows how the system works, and what makes CLC a great candidate for re-inventing combustion.

CHEERS acknowledges generous support from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 764697 and the China MOST program.

Understanding how CLC works – a brief animation

Our CHEERS project partner Total has commissioned a new animation describing the main principles of Chemical Looping Combustion. This is a very good introduction to the technology development scope of the CHEERS project.

An updated video will be published here soon.

CHEERS project introduced in 10th TOTAL China Scientific Forum in Chengdu

November 21, 2019

Today, the 10th Total China Scientific Forum (TCSF) opened in Chengdu. This is the city where the CHEERS project is based. The theme this year was “Innovative Low-carbon Energy”. The two-day gathering focused on the development of innovative technologies for the LNG industrial chain, low-carbon transportation and carbon dioxide capture, utilization and storage (CCUS). The forum serves as a platform for participants to share research results and present case studies. More than 200 experts and guests from renowned universities, research institutions, government and industry associations, well-known enterprises and innovative companies attended the forum.

Dongfang Electric Corporation (DEC), parent company of Dongfang Boiler Corporation (DBC), was invited to co-chair the event, while young scho

lars from another 2 Chinese partners Tsinghua University and Zhejiang University also presented themselves to exhibit their recent academic achievements in “Energy Future Innovation”. One of the major reasons to have such an event held in Chengdu was to better advertise the CHEERS project to the Chinese domestic market. Prof. Zhenshan LI from Tsinghua university and Dr. Mahdi YAZDANANAH from TOTAL jointly introduced the upcoming, latest progress and future prospect of the CHEERS project in the Forum, generating high interest and receiving wide rec

ognition from the audiences. A site tour to the cold mock-up model near Chengdu was also organized thereafter to some VIP guests.

“China has become one of the world’s most innovative and dynamic countries and is playing an active role in emerging energy technologies. As a flagship H2020 program undertaken in China, the CHEERS project will surely become an exciting, challenging and promising mission benefiting both European countries and China in developing affordable CCUS solutions,” says Zhonghua XU, VP, Head of TOTAL R&D Asia.

Author: Info CHEERS

CHEERS design milestone: delivery of Process Design Package, PDP

Achievement of an important milestone in CHEERS project: delivery of Process Design Package, PDP

CHEERS project has reached an important milestone by delivering the Process Design Package (PDP) of the Process Demonstration Unit (PDU). This dossier provides the basic design of the PDU and fixes all of the process variables, dimensions, and conditions. Regarding the fact that CHEERS is a development project and first of its kind, development of a solid process design is key to avoid any modification and changes in the coming steps to ensure successful progress of the project.

CHEERS project process design has been developed to answer project unique requirements by proposing a wide flexibility in terms of feedstock, Oxygen Carrier materials and particularly by allowing the possibility to test two Carbon Stripper Technologies developed by CHEERS partners. Safety and environmental considerations have been important criteria in the design where a dedicated flue gas treatment section is designed and detailed HAZID study carried out to ensure process safety.

The PDP has been prepared and issued with CHEERS international collaborative way. The Process Demonstration Unit process design is the result of the effort by four CHEERS partners, IFPEN, TSINGHUA, TOTAL and DONGFANG with the support of SINTEF as leader of Oxygen Carrier material development. It is the main outcome of the Pre-FEED study (Work Package, WP2) that will be delivered to the FEED phase (WP4) led by TOTAL.

Author: Info CHEERS