CHEERS demonstration facility construction is advancing rapidly to completion

The CHEERS consortium has designed and developed a 3 MWth demonstration facility for chemical looping combustion (CLC). This work began in 2017 and includes a comprehensive program of laboratory measurements, pilot-scale testing, cold-flow visualization rigs, and detailed simulation modelling on microscopic and macroscopic scales.

The CHEERS industrial partners, Dongfang Boiler Group and TotalEnergies, with close assistance from research partners Tsinghua University, IFPEN and SINTEF, are now well underway to build the facility on-site at the Dongfang Key Laboratory for Clean Combustion and Flue Gas Purification at Deyang, Sichuan Province, China.

The goal is to start testing on the completed facility in Q2 2023. Site preparation of the integrated CLC plant began in Q1 2022. Subsequent construction and assembly have progressed impressively. Most of the internal process equipment, much of which is unique to the CLC design, was completed in July-August.

- The footprint of the CLC system is about 270 square meters, and the highest process unit will be about 42 meters tall.

- The project aims to confirm the designed carbon capture rate of 96%.

- The capabilities of the CLC facility include enhanced system monitoring and data collection to enable a deeper understanding of the system performance. This will be used to improve future designs.

- The design of the CLC demonstration unit includes special adaptations to use at least two different types of solid fuels. As part of the design phase activities, these have been extensively modelled numerically and with an analogue 1/3 scale ‘cold flow’ hydraulic version of the final demonstration unit.

The following photos show some selected snapshots from the construction site and the factory producing the main process units.

The CHEERS project has received funding from the European Union’s Horizon 2020 research and innovation program under grant agreement No 764697. The project is also co-funded from National Key Research and Development Program of China by Chinese Ministry of Science and Technology (MOST) under grant agreement No 2017YFE0112500.

The project has also benefited from the work of the other project partners: Silesian University, Zhejiang University and Bellona.

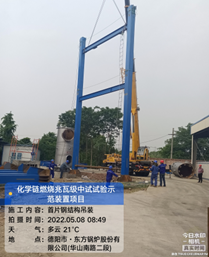

Raising the first steel beems for the support structure May 2022

Steel Support Frame June 2022

Steel Frame Support Structure in place August 2022

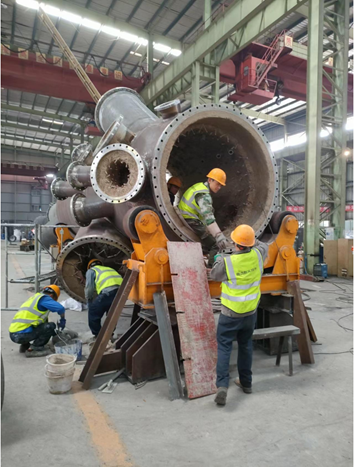

Installing a major process component in the demonstration facility August 2022

Manufacturing the main process units for CLC June 2022

Manufacturing the main process units for CLC June 2022

Transport of finished tank units to demonstration facility site June 2022

Building of the Largest Chemical Looping Combustion (CLC) Facility to Drive down the Cost of Carbon Capture

Paris/Deyang City (China), February 2, 2022 – CHEERS, a Sino-European consortium of leading researchers and manufacturers, has announced the construction of the world’s largest demonstration unit for Chemical Looping Combustion (CLC). This new stage will bring the project to a pre-industrial scale and confirm the potential of this key technology in driving down the cost of carbon capture and promoting the decarbonization of industry. Today the project reached a new milestone when TotalEnergies, Dongfang Boiler Group Co. (DBC), Tsinghua University and IFP Energies Nouvelles made the decision to build the 3MWth demonstration unit, with the potential to deliver 4-5 MWth.

Lowering the cost of carbon capture in power generation

CLC is an oxy-combustion technology used to convert biomass and fossil fuels in order to obtain a flow of pure CO2 suitable for low-cost capture. This integrated CO2 capture solution minimizes the use of costly gas separation processes like those retrofitted on existing combustion facilities. CLC generates heat that can be used to produce carbon-neutral electricity and/or steam.

“This unique project paves the way for the decarbonization of industries that currently generate a significant proportion of global carbon emissions. It could open the door to more cost-effective biomass and fossil fuel emission reductions at facilities around the world,” said project leader Dr. Nils Erland L. Haugen from SINTEF.

“Decarbonizing energy production is a major challenge. The TotalEnergies R&D teams carried out the research and design phases that enabled the CHEERS project partners to take this step and green-light the construction of a pre-industrial unit to validate the technical, economic and environmental performance of the CLC technology,” said Philip Llewellyn, Carbon Capture, Utilization and Storage Program Manager, TotalEnergies.

Developing technology from concept to reality

The investment decision marks the transition from the research and design phases to the engineering and construction phases, led by DBC at their technology development site in Deyang, near Chengdu in China.

The test campaign, planned for 2023, will bring the new concept to near-commercial maturity (Technology Readiness Level TRL 7) and form the basis for further upscaling and commercial project development.

The initial investment in the Deyang demonstration unit will total almost €10 million, in addition to the €10 million already invested in the research and development activities.

“The CLC process is the result of 13 years of research conducted by IFPEN and TotalEnergies on a laboratory scale and on a 10 KW pilot unit in IFPEN’s laboratories. The building of a demonstrator on a pre-industrial scale is therefore a very important step that will allow us to verify the performance of this CO2 capture technology and to prepare its implementation in power plants and biomass plants in particular,” said Florence Delprat-Jannaud, CO2 Coordinator, IFPEN.

**********************************

Facts and figures

- The planned CLC facility will convert a flow of solid fuels of about 4 MW measured in thermal energy content. The footprint of the facility will be about 270 square meters, and the highest process units will be about 40 meters tall.

- The project aims at a carbon capture rate of 96%.

- The capabilities of the CLC facility include enhanced system monitoring and data collection to enable a complete understanding of the system performance. This will be used to improve future designs.

- The CLC facility design includes special adaptations to use at least two different types of solid fuels.

The CHEERS project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 764697. The project is also co-funded from National Key Research and Development Program of China by Chinese Ministry of Science and Technology (MOST) under grant agreement No 2017YFE0112500.