The front-end engineering design (FEED) phase of the Chinese-European Emission-Reducing Solutions (CHEERS) project has now started – a major milestone in this project. When finished, it will be the world’s largest chemical looping combustion (CLC) demonstration plant.

The project is the last step before an industry-wide deployment of CLC technology. CLC generates steam for industrial applications or electrical power, without CO2 emissions thanks to its built-in ability to separate CO2. This means CLC can produce energy with zero carbon content. In addition, It can produce energy with negative carbon content when using feedstocks such as biomass. In this case, CLC enables the indirect capture of CO2 from the atmosphere, and the reduction of greenhouse gas content to the atmosphere.

The demonstration plant – to be built in China – will test the second-generation CLC technology at a capacity of 3MW and will be the largest of its kind using this new fuel-conversion technology in an operational environment.

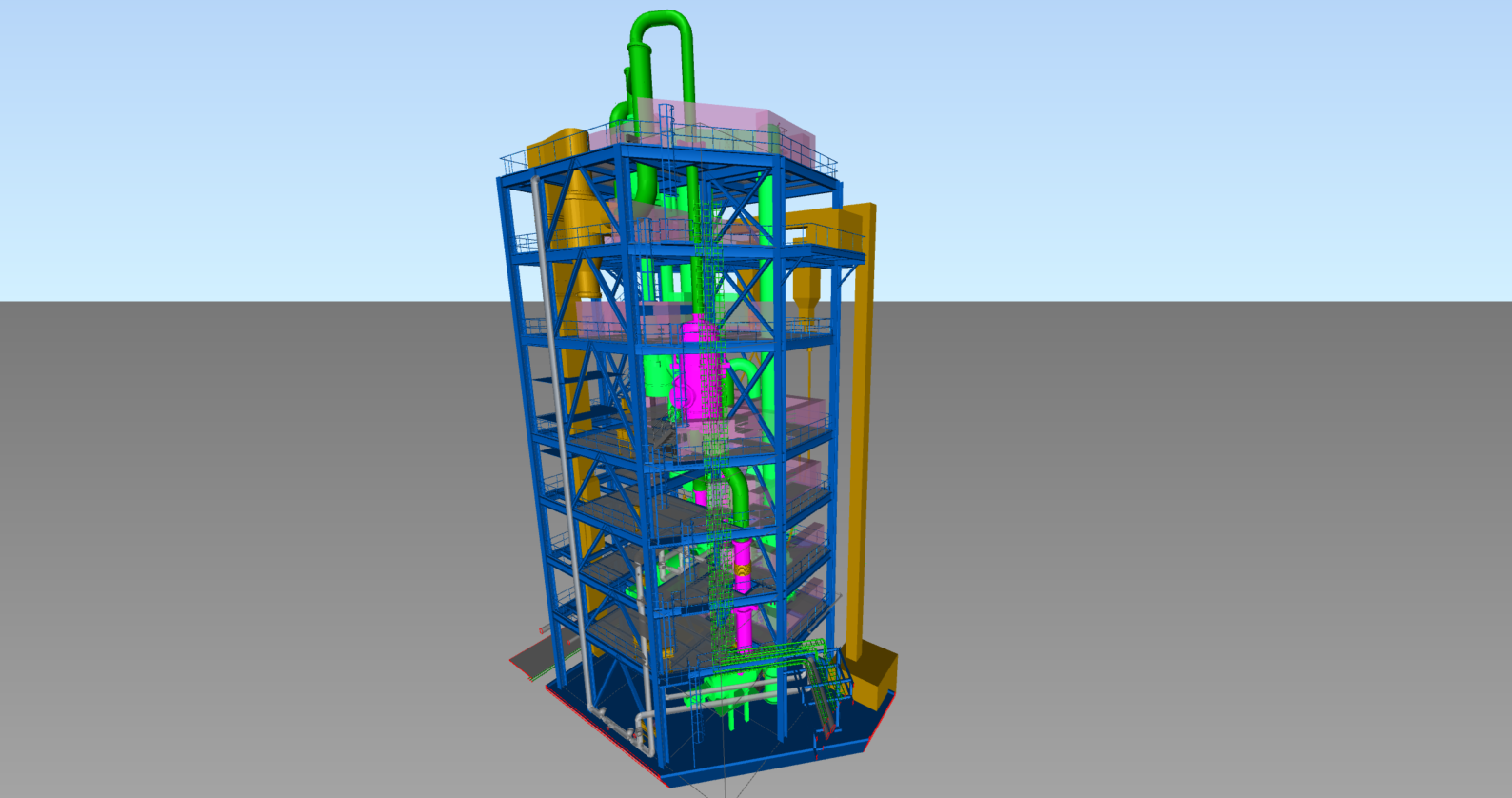

A 3-D engineering rendering of the planned demonstration plant

The ground-breaking concept has the potential to increase the efficiency of CO2 capture significantly, compared to existing carbon capture technologies and can remove up to 96 per cent of combustion-related CO2. The project offers a viable path to retrofit industrial combustion processes and is a major step towards the large-scale decarbonization of the refining, chemical and power industries.

Managed by TOTAL, the FEED was awarded to Worley, who will carry out the services from its Belgium and China offices. Once completed, the FEED results will be handed over to Dongfang Boiler Group Co Ltd, who will manage the detailed engineering, procurement and construction (EPC) of the plant.

The CHEERS project is financed partially by the EU’s Horizon 2020 Research and Innovation Programme and the Chinese Ministry of Science and Technology, with financial and industrial support from TOTAL, Dongfang Boiler Group Co Ltd, and other project partners.